Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPH718-23

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

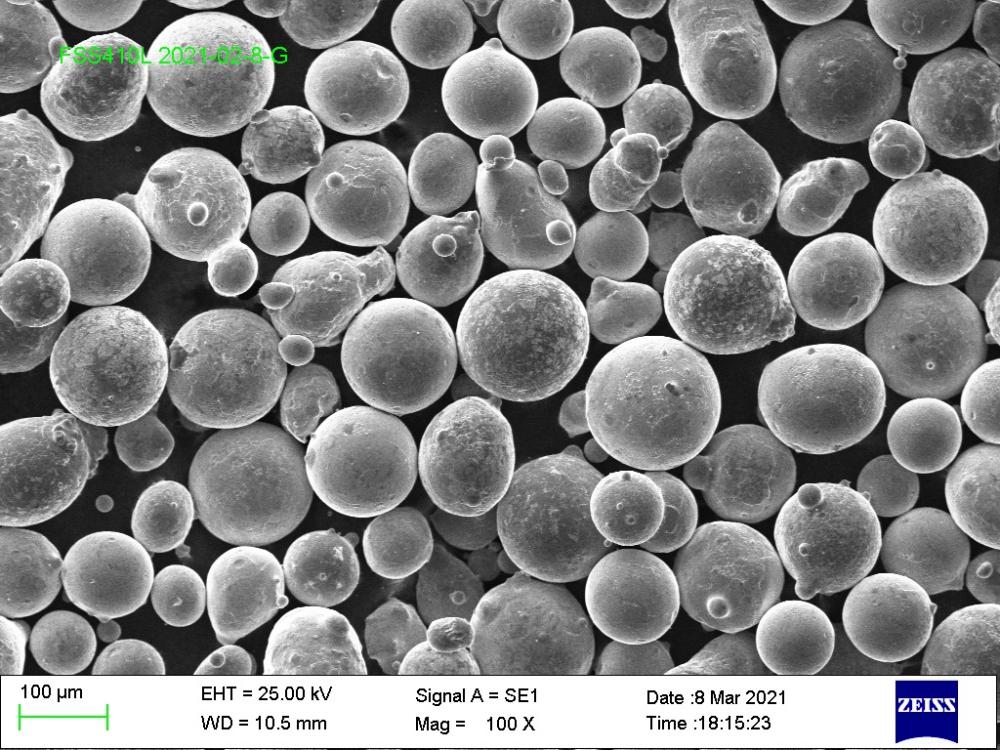

20-53 Um270-625mesh

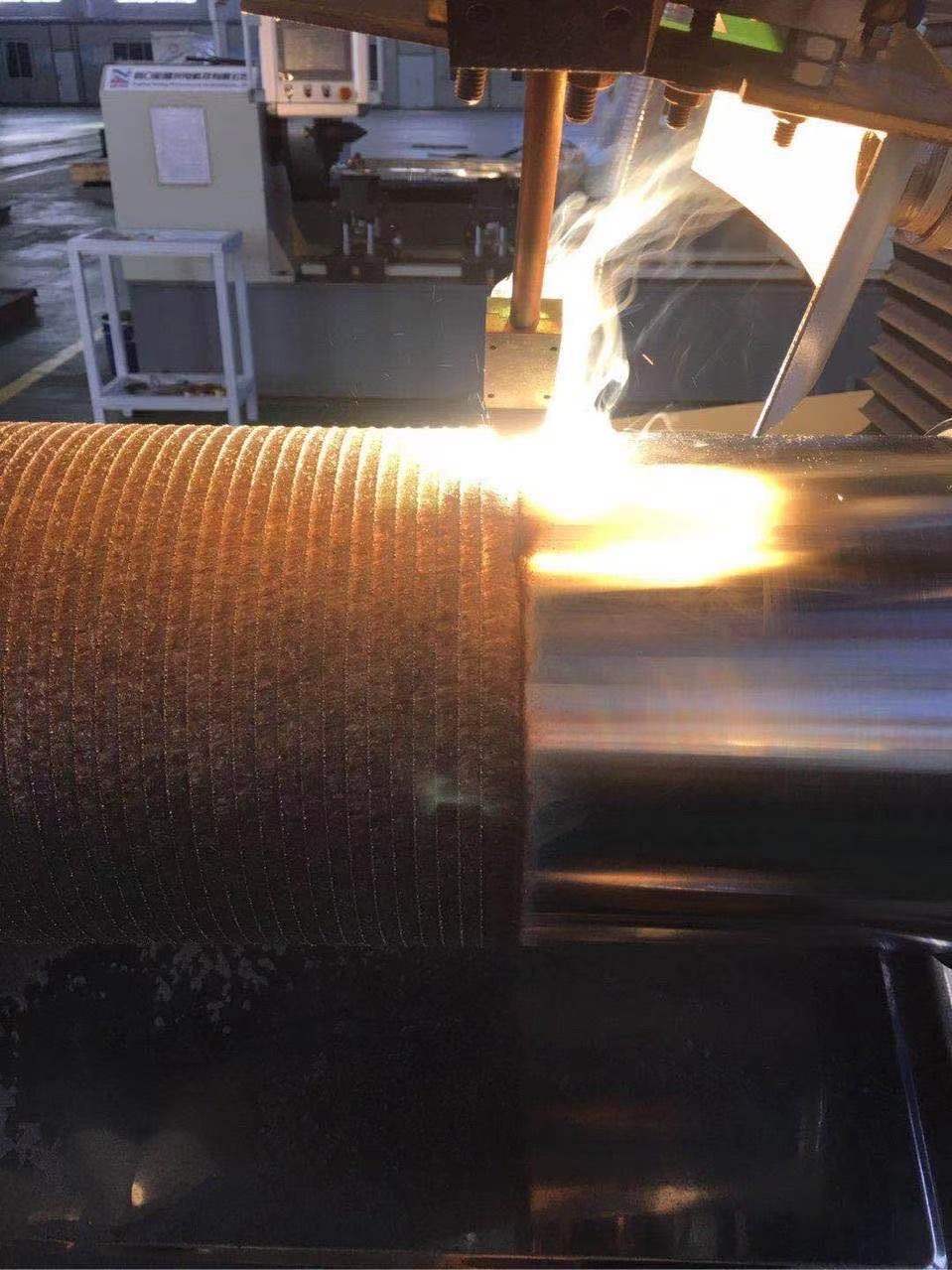

Introducing Inconel 718 POWER FOR LASER CLADDING, the ultimate solution for professionals seeking unparalleled performance in laser cladding applications. Crafted with utmost precision, this product harnesses the exceptional properties of Inconel 718, a high-strength, corrosion-resistant alloy, to deliver superior results. With its remarkable heat resistance and excellent weldability, it ensures precise and efficient laser cladding, even in the most demanding environments. Our Inconel 718 POWER FOR LASER CLADDING guarantees outstanding durability, enabling professionals to achieve flawless coatings, repairs, and enhancements with ease. Experience the power of Inconel 718 and elevate your laser cladding projects to new heights of excellence.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPNi23L-26

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-125 Um100-270mesh

Introducing our high-quality Nickel Alloy Powder for Glass Mould, designed to revolutionize the glass manufacturing industry. Crafted with utmost precision, this powder offers exceptional thermal conductivity and corrosion resistance, ensuring superior durability and longevity of glass moulds. With its unique composition, it guarantees optimal performance, allowing for flawless glass shaping and molding processes. Our Nickel Alloy Powder is meticulously tested and certified to meet stringent industry standards, providing peace of mind to manufacturers. Experience enhanced productivity, reduced downtime, and impeccable glass quality with our Nickel Alloy Powder for Glass Mould. Elevate your glass manufacturing capabilities today.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

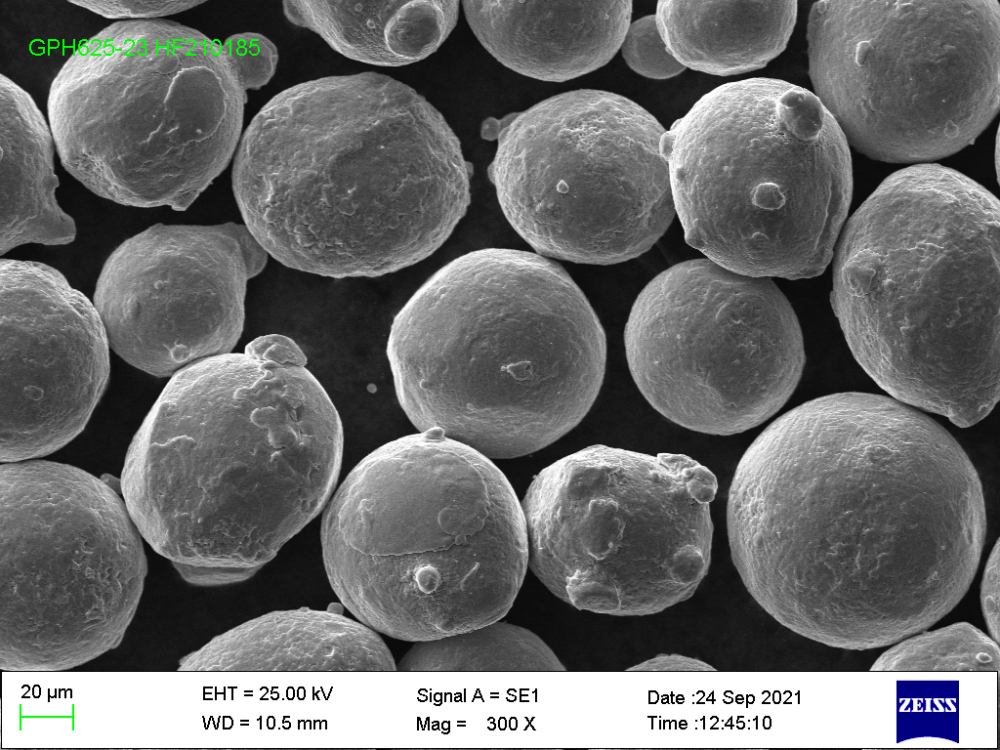

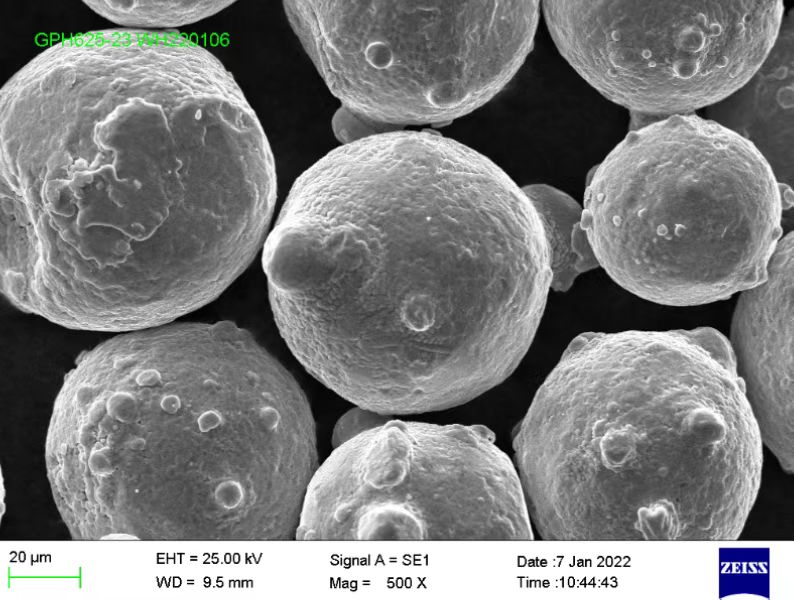

Model No.GPH625-23

Productivity500 tons/ year

TransportationOcean,Air,Express

Old and newNew

Video factory inspectionProvided

Mechanical test reportProvided

Marketing typeHot Product 2019

Core component warranty periodNot Available

Introducing our groundbreaking product, the Higher Temperature Alloy Powder Inconel 625. Designed specifically for professionals in various industries, this advanced alloy powder offers exceptional performance in extreme temperature environments. With its remarkable resistance to oxidation and corrosion, Inconel 625 ensures unparalleled durability and longevity. Its superior strength and excellent weldability make it an ideal choice for applications involving high-stress conditions, such as aerospace, chemical processing, and marine engineering. Backed by extensive research and manufactured to the highest standards, our Inconel 625 powder guarantees optimal results, providing professionals with a reliable and efficient solution for their demanding projects.

Save time! Get the best deal

Product Details:

BrandXTC

Supply Ability500tons/year

Place of OriginChina

Model No.GPNi60AA

Productivity500 tons/year

TransportationOcean,Land,Air

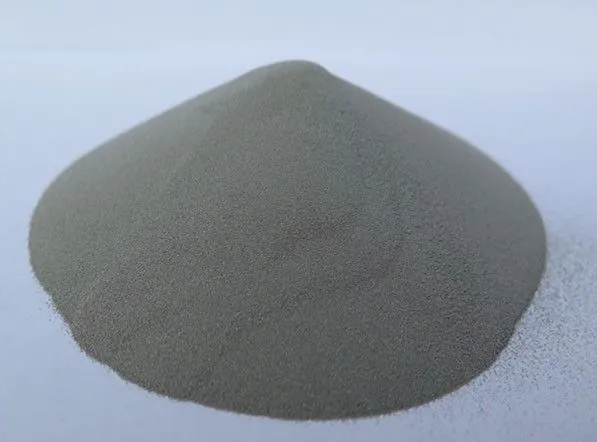

The Ni60 AA Alloy Powder is a high-quality product designed to meet the needs of various industries. With a hardness rating of 58-62HRC, this alloy powder offers exceptional strength and durability. It is made from nickel-based materials, ensuring excellent corrosion resistance and thermal stability. This powder is widely used in applications such as manufacturing cutting tools, wear-resistant coatings, and high-temperature components. Its fine particle size allows for easy dispersion and uniform coating, resulting in enhanced performance and longevity. Trust the Ni60 AA Alloy Powder for your industrial needs, and experience the superior quality it offers.

Product Details:

BrandXTC, Luoyang

Packaging5kg Plastic Bottle, 20kg Carton Box

Supply Ability500 tons/year

Place of OriginLuoyang, China

Model No.GPNi40AA-23

Productivity500 tons/year

TransportationOcean,Land,Air,Express,Railway

place of originChina

Introducing our highly sought-after NiCrBSi Nickel Based Alloy Powder! With a particle size ranging from 53-150um and an impressive HRC40 hardness level, this product is perfect for a wide range of applications. Its exceptional resistance to wear, corrosion, and high temperatures make it ideal for demanding environments. Whether you're in the aerospace, automotive, or manufacturing industry, this alloy powder will undoubtedly enhance the performance and durability of your products. Trust in its superior quality and reliability to deliver outstanding results. Upgrade your materials today with our NiCrBSi Nickel Based Alloy Powder!

Product Details:

BrandXTC LUOYANG

Packaging10kg plastic bottle

Supply Ability500 tons/year

Place of OriginLuoyang, China

Model No.GPH625-23

Productivity500 tons/year

TransportationOcean,Land,Air,Express,Railway

place of originChina

Introducing our premium-grade Inconel 625 Nickel Based Alloy Powder, meticulously engineered to exceed industry standards. With a particle size ranging from 53-150um, this high-performance powder offers exceptional corrosion resistance, excellent mechanical properties, and superior heat resistance. Crafted from a nickel-chromium-molybdenum alloy, it is ideal for applications in extreme environments such as aerospace, marine, and chemical industries. Our Inconel 625 powder guarantees outstanding weldability and is compatible with various additive manufacturing techniques, enabling the production of complex and durable parts. Trust in our product's reliability and versatility, making it the perfect choice for your critical projects.

$40

≥20Kilogram

Product Details:

BrandCXTC

Packaging10kg/bottle, 20kg/box

Supply Ability500T/year

Place of OriginChina

Model No.GPNiW15-28

Productivity500T/year

TransportationOcean,Land,Express,Others

place of originChina

Whether powderIs Powder

Introducing our latest innovation in the field of materials engineering - the Nickel Based alloy with 15% tungsten carbide powder. This exceptional product combines the strength and durability of nickel-based alloys with the added benefits of tungsten carbide. With a high tungsten carbide content of 15%, this alloy offers superior hardness, wear resistance, and toughness, making it ideal for applications in industries such as aerospace, automotive, and oil and gas. Its unique composition ensures enhanced performance and longevity, enabling our customers to achieve greater efficiency and reliability in their operations. Trust in our Nickel Based alloy with 15% tungsten carbide powder for unmatched quality and performance.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPNi0903B

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-106 Um140-270mesh

Introducing our high-quality Tungsten Carbide Powder, specially formulated for Glass Mould applications. This premium product is designed to provide exceptional hardness, wear resistance, and thermal stability, ensuring longevity and superior performance in glass manufacturing processes. Our Tungsten Carbide Powder offers excellent flowability, allowing for precise and consistent moulding, resulting in flawless glass products. With its fine particle size and exceptional purity, our powder guarantees optimal dispersion and uniformity, enabling smooth and efficient mould filling. Trust in our Tungsten Carbide Powder to enhance your glass moulding operations, delivering impeccable results and maximizing productivity.

$35

≥20Kilogram

Product Details:

Model No.GPFE1100

Introducing the GPFe1100 20-53um Metal Alloy Powder - Iron Based, the ultimate solution for professionals seeking high-quality metal alloy powders. Specially formulated with iron as its base, this powder offers exceptional strength, durability, and corrosion resistance. With a particle size range of 20-53um, it ensures precise and uniform distribution, enabling seamless integration into various manufacturing processes. Whether you're in the automotive, aerospace, or construction industry, this metal alloy powder guarantees superior performance and exceptional results. Trust in the GPFe1100 20-53um Metal Alloy Powder - Iron Based to elevate your projects to new heights of excellence.

$915

≥20Kilogram

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPS431-21

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

45-106 Um140-325mesh

The SS431 Alloy Laser Cladding is a high-quality product designed for buyers seeking durability and reliability. This product is specifically engineered to withstand harsh conditions and is ideal for applications that require resistance to corrosion and oxidation. With its laser cladding technology, the SS431 Alloy ensures uniform coating thickness and excellent bonding strength. This product offers exceptional wear resistance, making it suitable for various industries such as aerospace, automotive, and oil and gas. Invest in the SS431 Alloy Laser Cladding for a long-lasting and high-performance solution that will exceed your expectations.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

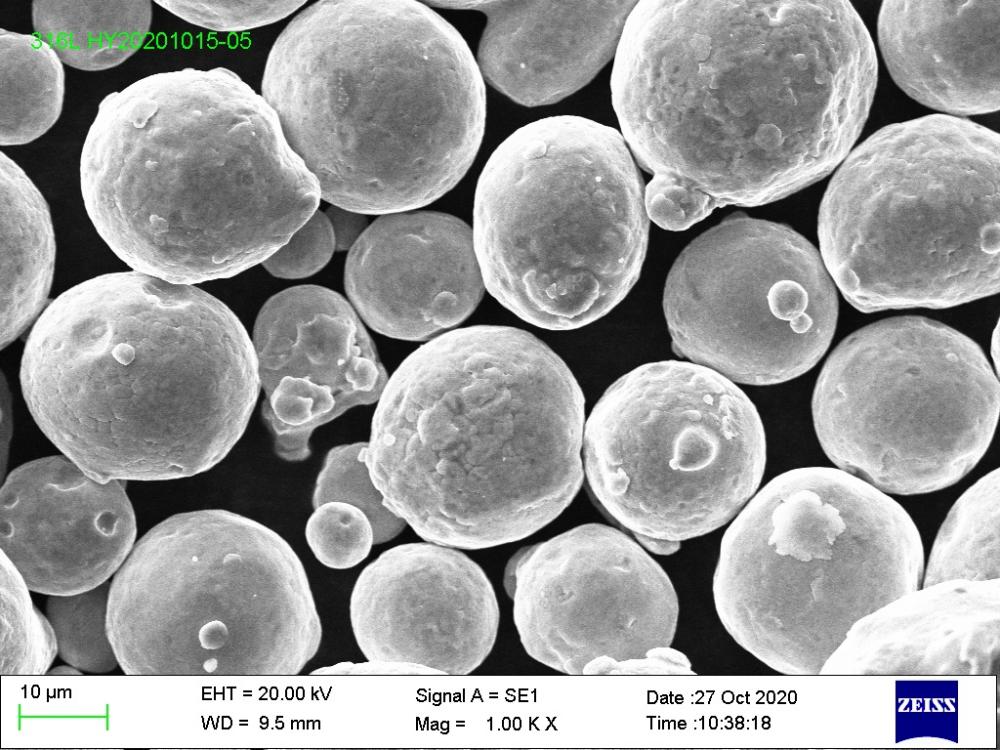

Model No.GPS316L-21

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

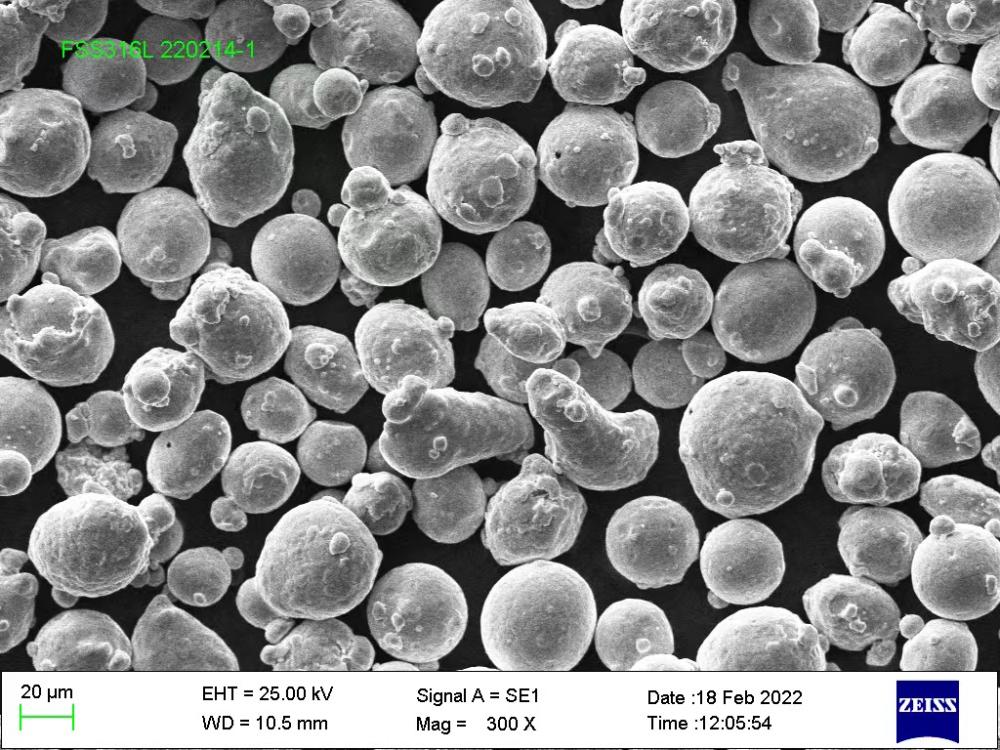

45-106 Um100-355mesh

Introducing our cutting-edge SS 316L for laser cladding, a revolutionary product that will elevate your manufacturing processes to new heights. Crafted with precision and expertise, this high-quality stainless steel offers unparalleled durability and resistance to corrosion, making it ideal for laser cladding applications. Its exceptional weldability ensures seamless integration into your projects, delivering flawless results every time. With its superior strength and excellent heat resistance, our SS 316L guarantees optimal performance and longevity. Whether you're in the aerospace, automotive, or oil and gas industry, this product is a game-changer, providing you with the reliability and efficiency you need. Upgrade your cladding capabilities with our SS 316L today!

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPS316-23

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-150 Um270-325mesh

Introducing our groundbreaking SS316L Power for Laser Cladding, designed specifically for professionals seeking unmatched precision and durability in their cladding applications. Crafted with high-grade SS316L stainless steel, this cutting-edge product delivers superior strength, corrosion resistance, and thermal stability, ensuring optimal performance even in the most demanding environments. With its advanced laser technology, our SS316L Power enables precise deposition of layers, facilitating seamless repairs and enhancing component life. Backed by extensive research and rigorous testing, this innovative solution guarantees exceptional quality and efficiency, empowering professionals to achieve unparalleled results in their laser cladding projects. Elevate your cladding capabilities with SS316L Power for Laser Cladding and experience the pinnacle of excellence.

$20

≥20Kilogram

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPS431-23

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-150 Um270-325mesh

Introducing the SS431 POWER FOR LASER CLADDING, the ultimate solution for professionals seeking unmatched precision and efficiency in laser cladding applications. This cutting-edge technology offers a powerful laser source that ensures exceptional material deposition, enabling professionals to achieve superior results every time. With its advanced features and robust design, the SS431 POWER is engineered to handle even the most demanding cladding tasks with ease. Its user-friendly interface and intuitive controls make it a breeze to operate, while its high energy efficiency guarantees cost-effective performance. Elevate your cladding game with the SS431 POWER FOR LASER CLADDING and experience unparalleled productivity and quality in your work.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPS420-21

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

45-106 Um140-325mesh

Introducing the SS420 Power for Laser Cladding, the ultimate solution for precision and efficiency in metal cladding applications. This state-of-the-art product combines cutting-edge technology with exceptional performance, allowing you to achieve superior results in record time. With its advanced features and robust design, the SS420 Power ensures seamless deposition of metal coatings, enhancing the durability and strength of your components. Whether you're in the automotive, aerospace, or oil and gas industry, this powerful tool guarantees unmatched precision, reduced downtime, and increased productivity. Upgrade your cladding process with the SS420 Power and experience the next level of excellence.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPS316L-23

Productivity500 tons/ year

TransportationOcean,Land,Air,Express,Others

place of originChina

53-150 UmCommon Laser Cladding Size

Introducing the "Laser Cladinator 3000" - the ultimate weapon in the battle against boring surfaces! Say goodbye to dull and lifeless materials, and hello to a world of vibrant and exciting possibilities! With its state-of-the-art 316L 53-150Micro technology, this bad boy will turn any surface into a work of art. It's like having a tiny army of microscopic artists at your fingertips, meticulously clad-ing every inch with precision and style. But wait, there's more! The Laser Cladinator 3000 also comes with an optional "Boss Mode" feature, where it transforms into a tiny but mighty boss figure, complete with a miniature suit and tie. Watch in awe as your colleagues' jaws drop at the sight of your powerful and stylish laser-cladding boss! Get ready to revolutionize your workplace with the Laser Cladinator 3000 - because who said lasers and humor don't mix?

$16

≥20Kilogram

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPS316L-6

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

20-53 Um270-625mesh

Introducing our top-of-the-line laser cladding product, crafted with precision using the highest quality 316L stainless steel. With a micro thickness ranging from 20 to 53, this product ensures exceptional durability and longevity for any industrial application. Laser cladding with 316L stainless steel offers superior resistance to corrosion, heat, and wear, making it ideal for demanding environments. Whether you need to enhance the surface properties of components or repair worn-out parts, our laser cladding product guarantees excellent results. Trust in the reliability and performance of our 316L 20-53micro laser cladding solution for all your industrial needs.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPCo21-23

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-150 Um100-270mesh

Introducing Co21 POWDER FOR LASER CLADDING - the ultimate secret weapon for professionals who want to turn their boring office into a wild disco party! This magical powder is not your average laser powder, oh no! It's infused with the power of unicorn laughter and fairy dust, guaranteed to make your colleagues do the Electric Slide in their suits! Simply sprinkle this enchanted powder on any surface, and watch as it transforms into a dazzling light show that will have your boss questioning your sanity. But hey, who needs a promotion when you have a laser-clad dance floor, right? Get ready to boogie your way to success with Co21 POWDER FOR LASER CLADDING!

$50

≥5Kilogram

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPCo6-23

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

45-106 Um100-325 mesh

Introducing Co6 POWDER FOR LASER CLADDING - the ultimate solution for precision metal deposition! This high-quality powder is specifically designed for laser cladding applications, ensuring exceptional performance and durability. With its unique composition, Co6 POWDER offers excellent resistance to wear, corrosion, and high temperatures, making it ideal for a wide range of industrial applications. Whether you need to repair, enhance, or create intricate metal components, this powder delivers outstanding results. Its fine particle size ensures precise deposition, enabling you to achieve flawless finishes and maintain dimensional accuracy. Trust Co6 POWDER FOR LASER CLADDING for superior quality and unmatched reliability!

$40

≥5Kilogram

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPCo6-21

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

45-106 Um100-325mesh

Introducing our top-of-the-line Co6 alloy powder, specifically designed for laser cladding applications. This high-quality product boasts exceptional wear resistance and superior corrosion protection, making it the ideal choice for various industrial sectors. With its precise composition and fine particle size, our Co6 alloy powder ensures excellent bonding with the substrate material, resulting in a flawless and durable cladding layer. Its exceptional thermal conductivity guarantees efficient heat dissipation, minimizing the risk of distortion during the cladding process. Trust our Co6 alloy powder to enhance the performance and longevity of your components, enabling you to achieve unparalleled productivity and cost-effectiveness.

$50

≥5Kilogram

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPCo12-23

Productivity500 tons/ year

TransportationOcean,Air

place of originChina

Particle size-106/+45 μm, -45/+15 μm

Powder typeGas atomization

Introducing Co12 Powder for Laser Cladding - the ultimate solution for all your metal cladding needs! This high-performance powder is specifically designed to enhance the durability and strength of metal surfaces, making it perfect for a wide range of applications. Whether you need to reinforce worn-out parts or protect against corrosion, Co12 Powder ensures impeccable results every time. Its advanced composition guarantees superior adhesion and excellent resistance to extreme temperatures, ensuring longevity and reliability. With easy application and compatibility with various laser cladding systems, Co12 Powder is a must-have for industries like aerospace, automotive, and manufacturing. Experience the power of Co12 Powder and elevate your projects to new heights!

$35

≥20Kilogram

Product Details:

Model No.GPCo06-4

TransportationOcean,Land,Air,Express

Product Details:

BrandXTC

Packaging10kg/bottle

Supply Ability500 tons/year

Place of OriginCHINA

Model No.GPCo06-23

Productivity500 TONS

TransportationOcean,Air

Introducing our high-performance Cobalt Base Alloy Powder Co 6, designed specifically for professionals in need of superior strength and durability. Crafted using advanced metallurgical techniques, this cobalt alloy powder offers exceptional resistance to wear, corrosion, and high temperatures, making it ideal for demanding industrial applications. With its excellent weldability and machinability, our Co 6 powder ensures seamless integration into existing projects, reducing downtime and maximizing efficiency. Whether you're in aerospace, automotive, or oil and gas industries, our Cobalt Base Alloy Powder Co 6 is your go-to solution for long-lasting, reliable performance. Trust in our expertise and elevate your projects to new heights.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPCo12-23

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-150 Um100-270mesh

Introducing the Laser Cladding Co12 Powder, a cutting-edge solution for enhancing the durability and performance of your industrial equipment. This premium powder is specifically designed to be used in laser cladding processes, providing an exceptional protective coating that resists wear, corrosion, and high temperatures. With its unique composition and advanced technology, the Laser Cladding Co12 Powder ensures superior bonding to the substrate, resulting in a longer lifespan and reduced maintenance costs for your machinery. Trust in this high-quality powder to extend the life of your equipment and improve its overall efficiency. Invest in Laser Cladding Co12 Powder for unmatched protection and longevity.

Product Details:

BrandXTC

Packaging5kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPNi2701B-1

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

20-53Um100-270mesh

Introducing WC Base Laser Cladding Powder, an innovative solution designed to revolutionize metal surface enhancement and repair processes. This high-quality powder is specifically formulated with tungsten carbide (WC) particles, ensuring exceptional hardness, wear resistance, and thermal stability. Our laser cladding powder offers superior bonding capabilities, enabling precise and efficient deposition onto various substrates. With its exceptional metallurgical properties, this powder is ideal for applications in industries such as aerospace, automotive, and oil & gas. Experience enhanced performance, extended equipment lifespan, and reduced maintenance costs with WC Base Laser Cladding Powder, the ultimate choice for advanced surface engineering.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPNi2701B-1

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

20-53Um100-270mesh

Introducing the WC Blend with Ni Laser Cladding Powder, the ultimate solution for professionals seeking high-performance coatings. This cutting-edge product combines the superior hardness and wear resistance of tungsten carbide (WC) with the outstanding bonding capabilities of nickel (Ni) for unmatched durability and protection. Ideal for various industrial applications, including mining, oil and gas, and manufacturing, this laser cladding powder ensures enhanced surface properties, such as corrosion resistance and thermal stability. With its precise composition and advanced laser cladding technology, this product guarantees efficient and cost-effective coatings that will withstand even the harshest operating conditions. Upgrade your professional projects with the WC Blend with Ni Laser Cladding Powder and experience unmatched performance and longevity.

Product Details:

BrandXTC

Packaging5kg/bottle

Supply Ability500tons/year

Place of OriginChina

Model No.GPNi0801B

Productivity500tons/year

TransportationOcean,Land,Air

place of originChina

Introducing our high-quality 60% Spherical Tungsten Carbide Blend Powder, perfect for various industrial applications. This product is meticulously crafted using advanced techniques to ensure exceptional performance and durability. With its spherical shape, it offers improved flowability, making it easier to handle during manufacturing processes. Our tungsten carbide blend powder boasts a 60% concentration, guaranteeing enhanced hardness and wear resistance. Whether you need it for cutting tools, wear parts, or any other application that demands superior strength, this product is an excellent choice. Invest in our 60% Spherical Tungsten Carbide Blend Powder to elevate your manufacturing capabilities and achieve outstanding results.

Product Details:

BrandXTC

Packaging5kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-150Um100-270mesh

Introducing our groundbreaking 60% Spherical Cast Tungsten Carbide Laser Cladding Powder, a cutting-edge solution revolutionizing industrial wear resistance. Engineered using advanced technology, this high-performance powder offers unparalleled hardness and durability, making it ideal for protecting critical components against extreme abrasion, erosion, and impact. With its exceptional spherical cast structure, our powder ensures optimal flowability and uniform deposition during laser cladding processes, guaranteeing superior coating quality and consistency. Backed by rigorous testing and stringent quality control measures, our product guarantees extended equipment lifespan, reduced downtime, and significant cost savings. Stay ahead of the competition with our 60% Spherical Cast Tungsten Carbide Laser Cladding Powder and experience unmatched performance in wear protection.

Product Details:

BrandXTC

Packaging10kg/Bottle, 20kg/Package

Supply Ability500 tons/year

Place of OriginChina

Model No.GPNi 2701B

Productivity500 tons/ year

TransportationOcean,Air,s

place of originChina

53-150Um100-270mesh

Introducing our cutting-edge WC Blend with Ni powder for laser cladding, designed exclusively for professionals seeking unmatched performance and precision. This innovative product combines the exceptional hardness and wear resistance of tungsten carbide with the superior bonding capabilities of nickel, resulting in a robust and durable surface coating. Ideal for applications requiring high thermal conductivity and corrosion resistance, our WC Blend with Ni powder ensures enhanced productivity and extended tool life. Experience seamless cladding and achieve flawless results with this advanced solution, trusted by industry experts worldwide. Elevate your projects with the ultimate fusion of strength, reliability, and efficiency.

Product Details:

BrandXTC LUOYANG

Place of OriginLUOYANG, CHINA

Model No.GPMo702

Productivity500 tons/year

TransportationOcean,Land,Air,Express

place of originChina

Introducing our Pure Molybdenum bar, the ultimate smelting additive for superior performance. Crafted with precision, this bar is specifically designed to enhance the smelting process by providing exceptional thermal conductivity and high melting point properties. Its pure molybdenum composition ensures durability and resistance to corrosion, making it a reliable choice for various smelting applications. With its excellent heat resistance and stability, our Pure Molybdenum bar guarantees consistent and efficient smelting results. Trust in its exceptional quality and elevate your smelting operations to new heights.

Product Details:

BrandXTC

Packaging100kg per barrel

Supply Ability1000tons per year

Place of OriginChina

Model No.GPMo701

Productivity1000 tons

TransportationOcean,Land,Others

place of originChina

Introducing the Pure Mo Bar, the ultimate tool for professionals in the metal smelting industry. Crafted with precision and expertise, this bar is designed to meet the demanding needs of your work. Made from pure molybdenum, it offers exceptional strength and durability, ensuring long-lasting performance. The Pure Mo Bar is perfect for various applications, including alloy production, steel manufacturing, and high-temperature furnaces. Its high melting point and excellent thermal conductivity make it ideal for withstanding extreme heat. With its sleek design and reliable functionality, the Pure Mo Bar is a must-have for professionals seeking top-notch performance and efficiency in metal smelting.

$40 - 60 /Kilogram

Product Details:

BrandLuoyang Golden Egret Geotools Co., Ltd.

Packaging25kg /iron drum

Supply Ability350 tons/year

Place of OriginChina

Model No.GPMo702

TransportationOcean,Land,Air,Express

place of originChina

Introducing our High Pure Molybdenum Bar, a game-changer in the metallurgical industry. Crafted with utmost precision and using advanced purification techniques, this product offers exceptional purity and unmatched performance. The molybdenum bar boasts an impressive melting point, making it ideal for applications requiring high-temperature resistance, such as aerospace and nuclear industries. Its superior strength and corrosion resistance ensure longevity and reliability in extreme conditions. With a smooth surface finish and precise dimensions, our High Pure Molybdenum Bar is ready to be seamlessly integrated into your manufacturing processes. Trust in its exceptional quality to elevate your production capabilities and surpass industry standards.

Save time! Get the best deal

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.